Increasing efficiency...

Software for Operational Excellence

- A toolbox with more than 40 apps to increase efficiency

- Supplemented by real machine and operating data

- For continuous and methodical improvement

- Integrated AI-Assistant

Module

Lean Management

- Methods developed in Japan and successfully used worldwide to increase efficiency

- Apps: Kaizen, Gemba, Kanban, 5S, Muda, ...

- Take advantage of the benefits of digital lean management (time savings, evaluable, available everywhere,...)

Kaizen

The Kaizen app promotes continuous improvement. Suggestions are systematically recorded and tracked using PDCA (Plan-Do-Check-Act).

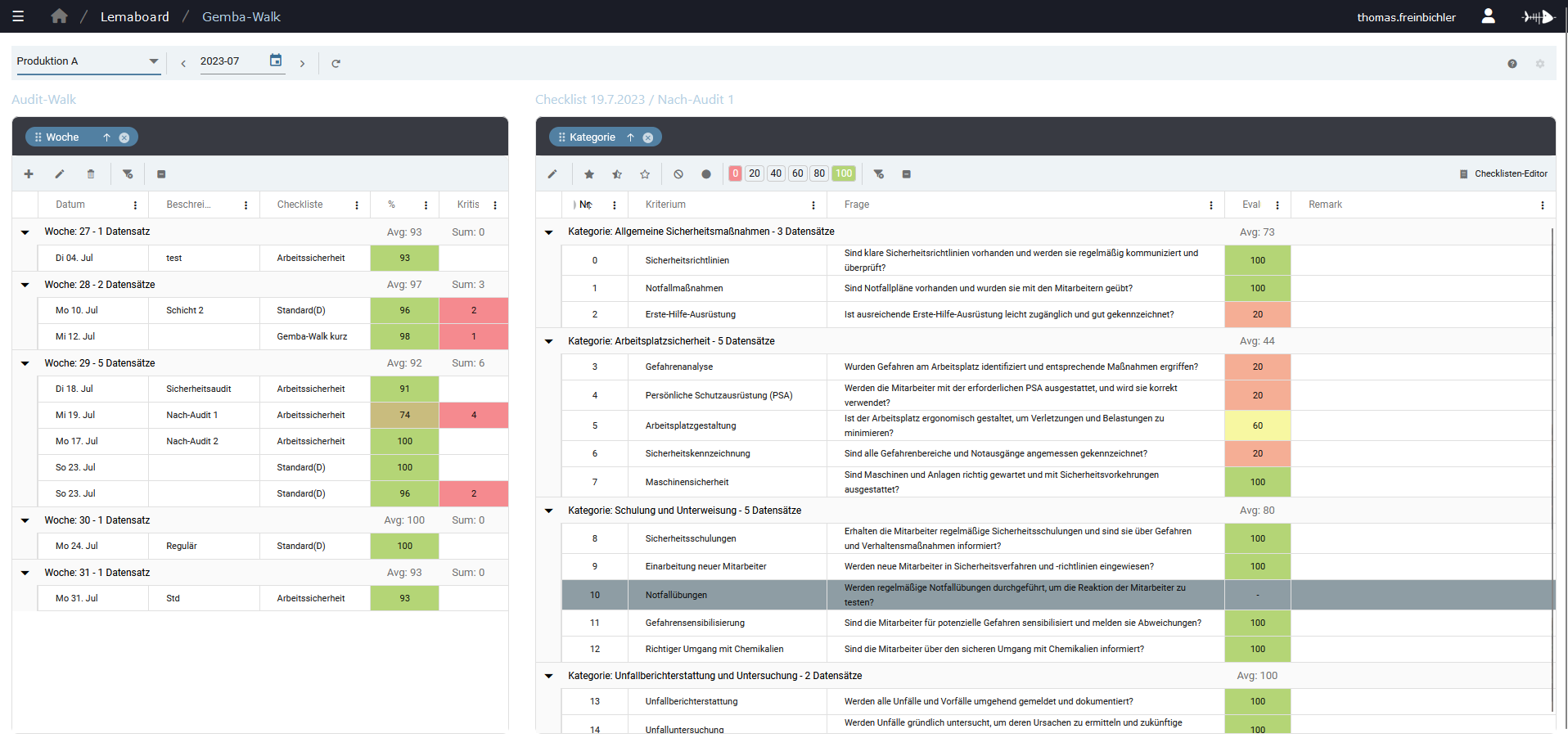

Gemba

Fewer meetings, more practice: The Gemba Walk app enables targeted tours and audits with evaluable checklists.

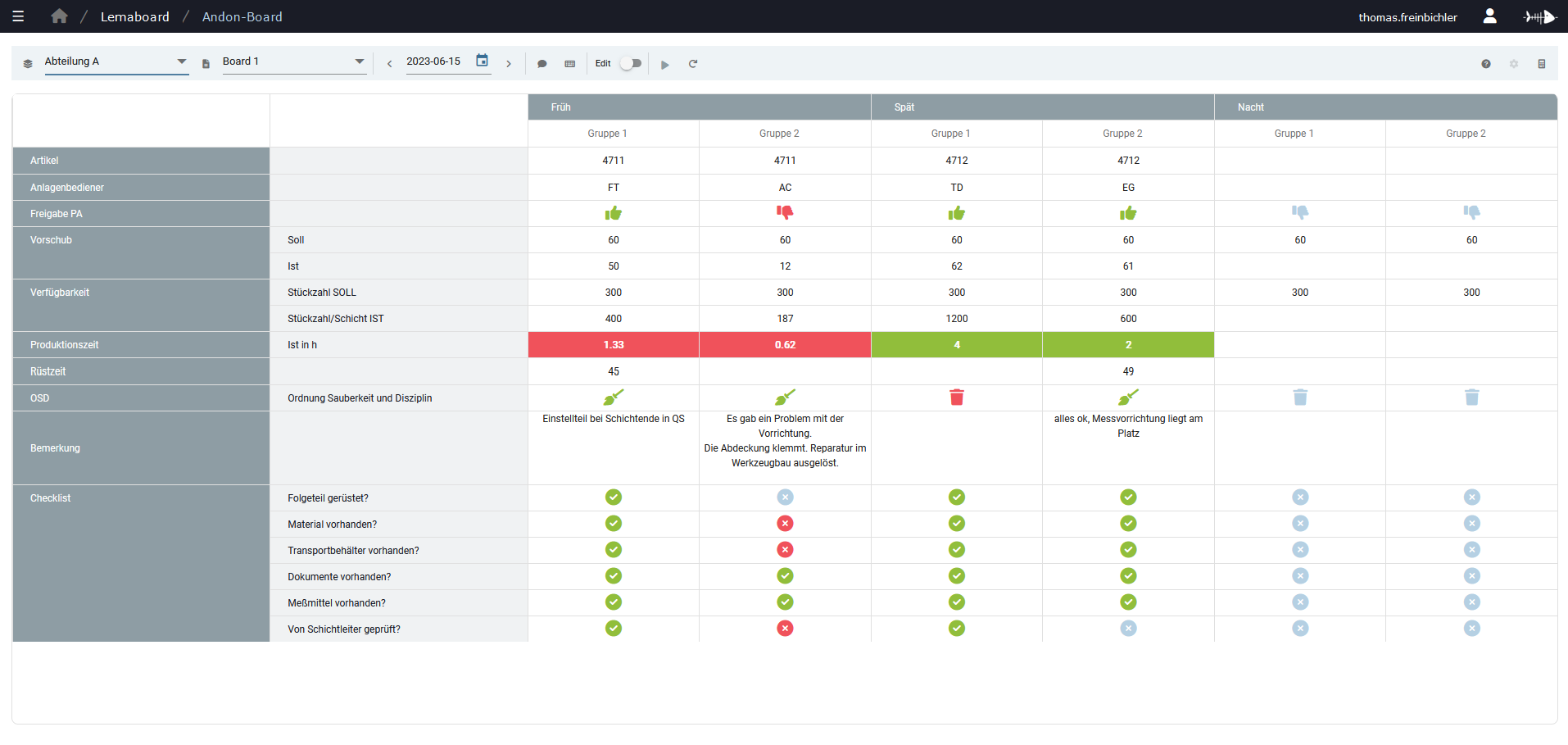

Andon

Individual boards for daily shop floor meetings with reporting functions for time-based evaluations – ideal as a structured shift log.

Ishikawa

The Ishikawa app helps to visually analyze the causes of problems and discuss them in a structured manner.

Muda

Eliminate waste – focus on value-adding activities.

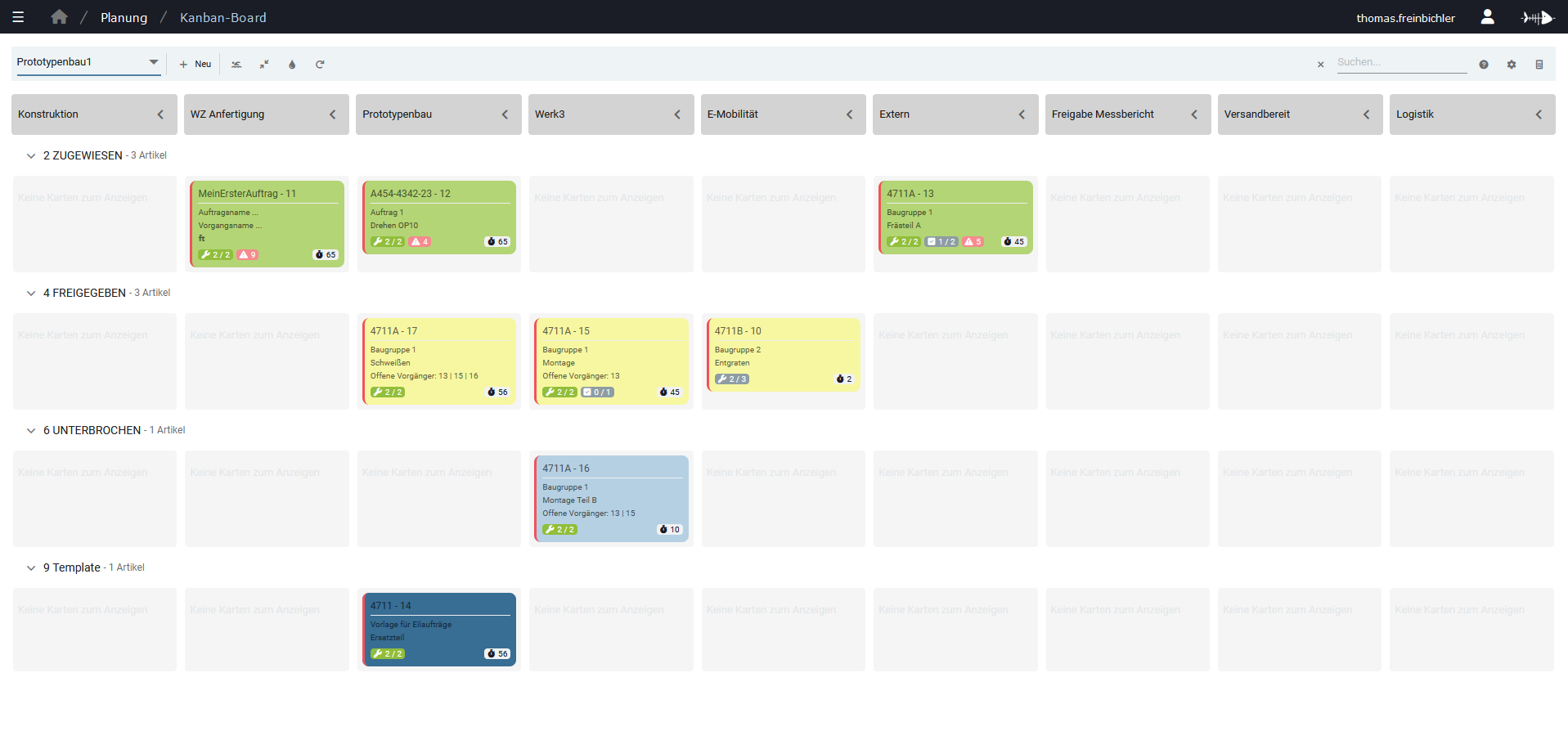

Kanban

The Kanban app clearly visualizes tasks and supports self-regulating control according to the pull principle.

5S

The Kanban app clearly visualizes tasks and supports self-regulating control accSystematic recording and optimization of order and cleanliness in the workplace.

TPM

Guided maintenance with minimal waste and continuous improvement – cyclical or runtime-dependent.

Kamishibai

Red and green cards for recurring tasks – with automatic, cyclical reset for maximum efficiency.

SMED

Reduce setup times – based on Shigeo Shingo’s method for efficient workshop changeovers.

Lean Wiki

A knowledge database in blog format, where you can add your own content – including over 25 practically explained lean methods.

Proven methods and digitalisation

Lean-Management everywhere

Proven Methods and Digitalization

Digital Lean Management – Versatile

Lean management, originally developed by Toyota, focuses on value-adding processes without waste. Today, lean methods are used in areas such as:

- Lean Administration

- Lean Engineering

- Lean Healthcare

- Lean Leadership

- Lean Production and much more

With our apps, you can apply lean methods digitally and efficiently in various areas and benefit from the advantages of digitalization.

Module

Safety Management

- Monitor occupational safety – document regular audits and safety instructions.

- Record accidents and risks – evaluate work accidents, deviations and safety measures.

- Ensure fire protection – centrally manage and access inspections and specifications.

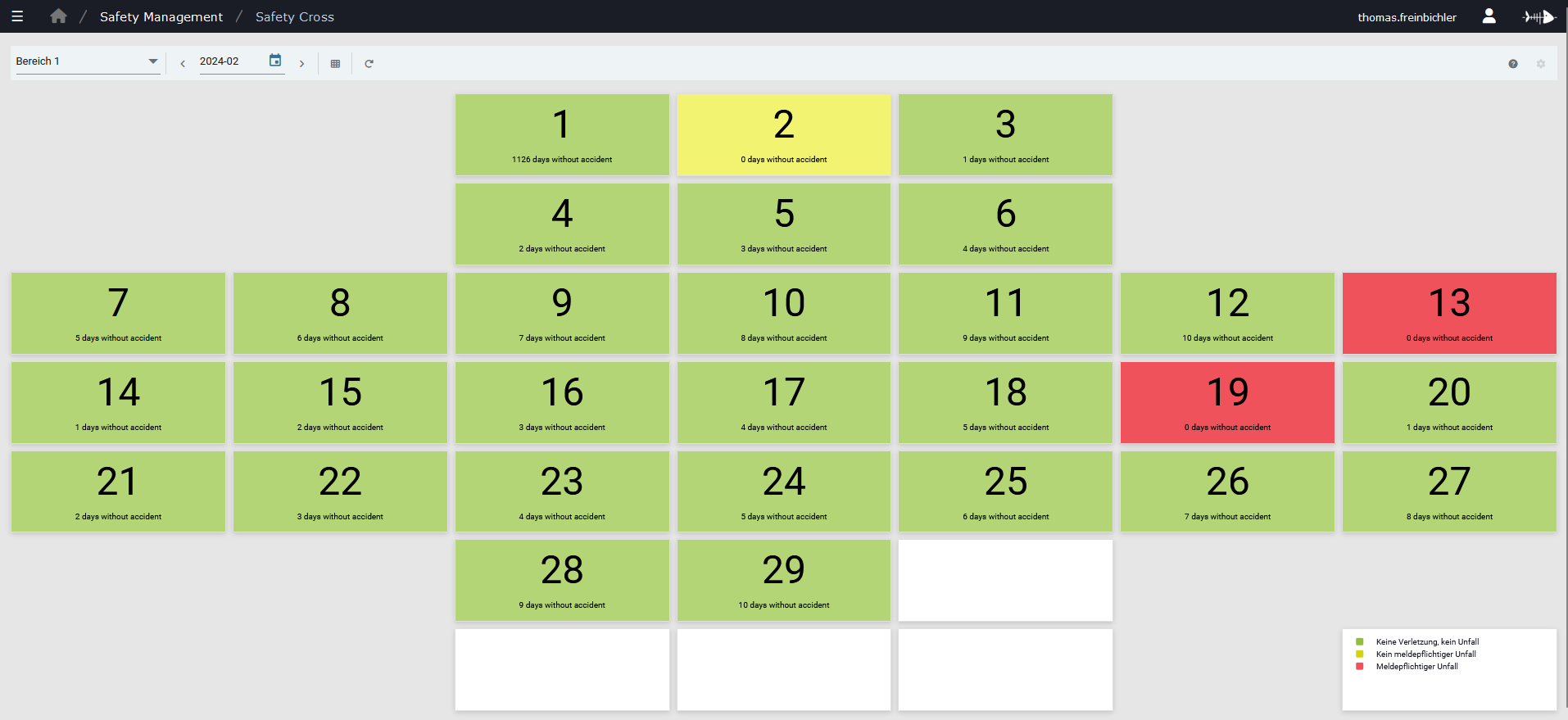

Safety Cross

Visualizes “days without work accident” as a safety cross and records work accidents.

Work Safety

Regular audits using a checklist with evaluable results and deviations.

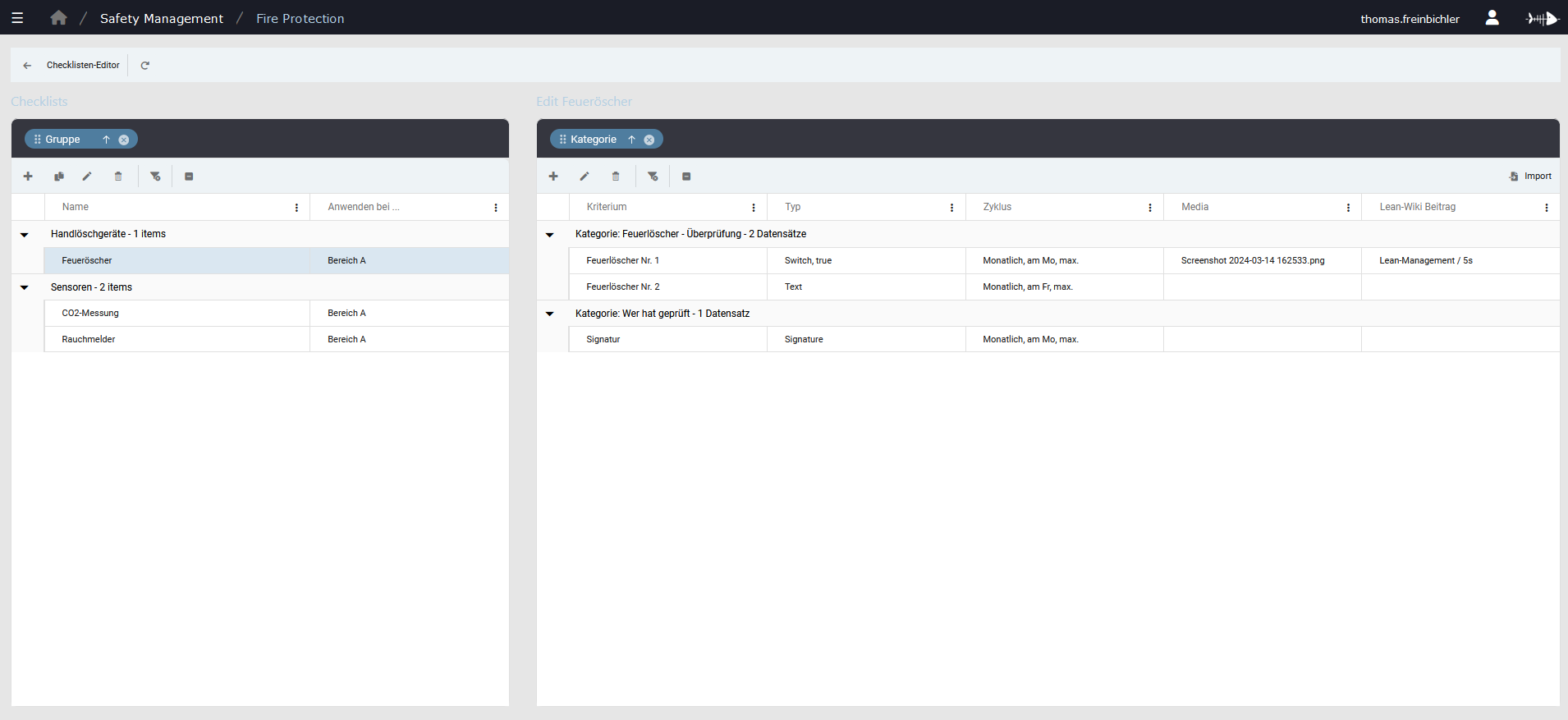

Fire-Protection

Central administration and retrieval of regular fire safety inspections via audit.

Safety Instruction

Documentation of general and workplace-specific safety instructions.

"Safety Management" insights...

Module

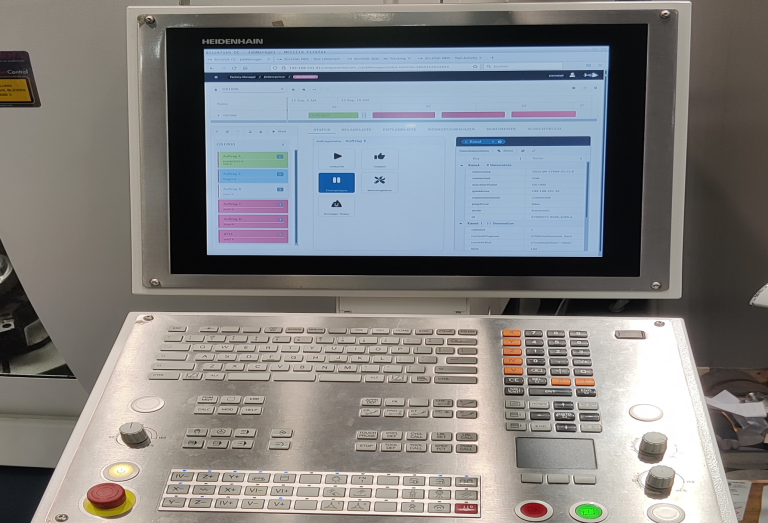

Data Collection

- mdc is an app platform for machine and operational data acquisition

- Flexible data-hub

- More than 100 interface-plug-ins

- Solutions also for old machines

- Machine data supplemented by operator-feedback

- Achieve Operational Excellence (OPEX) by using real data

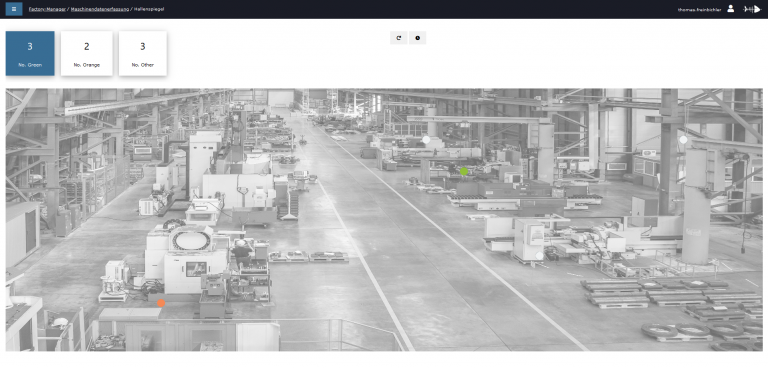

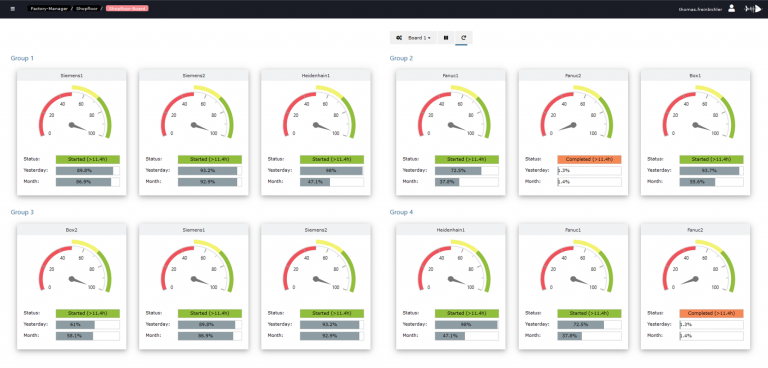

Dashboard

All relevant data, such as current status or performance, at a glance.

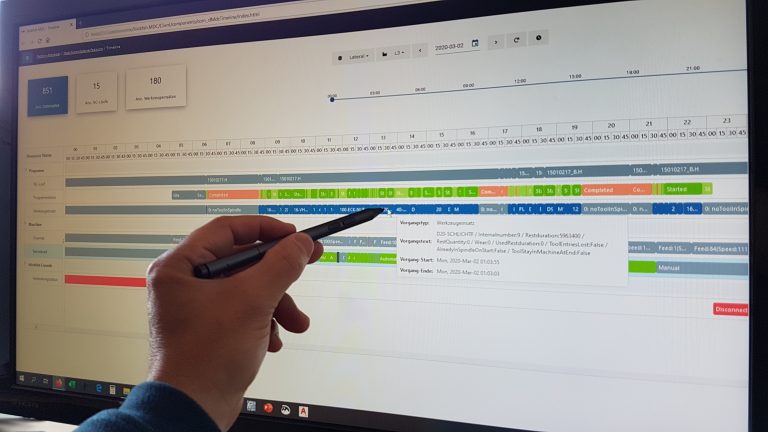

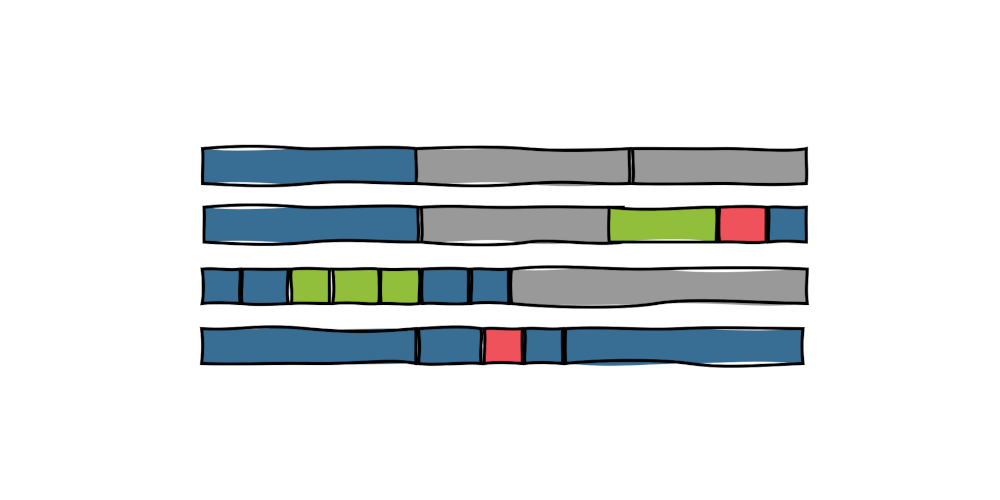

Timeline

The timeline shows time blocks (e.g. program statuses, tool usage, errors, piece counters, ...) on a daily basis along the time axis. The complete daily routine can be seen at a glance.

NC-Analysis

NC analysis is a typical application for series production. Here, the actual machine running times and non-productive times can be seen for each NC program in the trend analysis.

NC-Tracking

Automatic detection and logging of NC-program version and program changes for clear traceability.

Tool-Analysis

Every tool use is recorded in detail. With the app tool analysis, usage can be analyzed from many perspectives.

Tool-Magazine

The tool magazine app shows the current status of the tool magazine of each machine, including all detailed tool data. This allows the central presetting to be designed efficiently and tool searches and downtimes to be minimized.

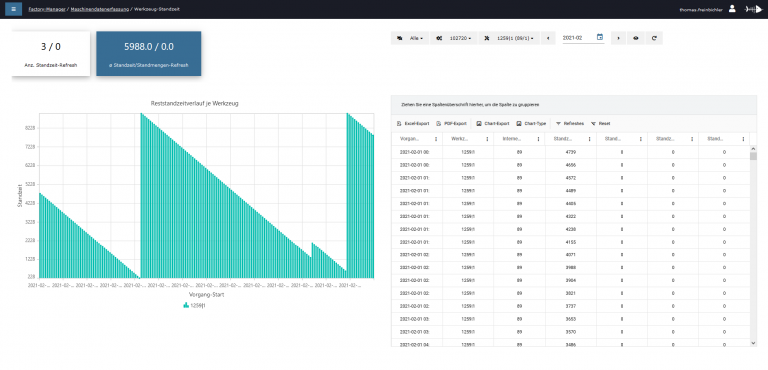

Tool-Lifetime

In addition to tool usage, remaining tool-lifetime history is also logged. The app shows the remaining lifetime in a burn-down diagram, also with reference to use for various NC programs.

Error-Analysis

Targeted error analysis to identify the major causes of disruption.

Feedback

Machine data acquisition automatically records downtimes. These downtimes are justified by the employee in the feedback app according to category and optionally with free text. The result is the basis for a precise cause analysis and optimization measures.

Stickfish-Console

The modular data-hub

The Stickfish Console is a modular data hub, comprising a core and variable interface plug-ins. It reads, processes, converts, and redistributes data, seamlessly integrating into workflows.

A prime use case is extracting machine control data, mapping and transferring it to an ERP system. Beyond this, numerous other applications exist. The data hub can serve as a background service, providing data to your app, or you can employ our visualization and processing apps.

A large number of Interface Plug-Ins

- Siemens S7 (Powerline and Solution Line

- Heidenhain iTNC

- Fanuc i

- Num (grinders, …)

- EOS (3D printer)

- Beckhoff ADS (device and fieldbus-independent interface to Beckhoff TwinCAT

- OPC-UA … (more than 100 interfaces based on OPC-UA – ask us!)

- MQTT (open message protocol for machine-to-machine communication M2M)

- Modbus TCP/RTU

- …

- Web server, cloud (connection to cloud services)

- FTP (File Transfer Protocol)

- JSON (Javascript Object Notation)

- XML (Extensible Markup Language)

- Web service (integration of web services – REST, SOAP)

- …

- CSV (Comma Separated Values)

- Excel

- ARC (Siemens NC program)

- H (Heidenhain NC program)

- …

- MS SQL (Server and Express)

- MySQL (one of the world’s most popular relational database systems)

- MongoDB (most widely used NoSQL database)

- MS Access (Microsoft Access)

- OLE DB (Object Linking and Embedding, Database)

- ODBC (Open Database Connectivity)

- ORACLE (Oracle Database)

- …

- SAP IDOC (standardized interface for SAP connection)

- MS Outlook (send data directly in MS Outlook as a calendar entry or email)

- camLine (interface to an MES system)

- Qlik Sense (integration into the data analysis software Qlik Sense – Business Intelligence)

- Power BI (interface to Microsoft Power BI, including real-time streaming)

- …

The Stickfish-Blackbox

Given the diverse nature of the machine landscape, there are instances

where hardware solutions become necessary. This is particularly true for

older machines or when decentralized data acquisition is involved. The Stickfish Blackbox is crafted to adhere to industry standards, seamlessly capturing traffic light signals, piece counters, sensors, and energy data from a wide range of machines.

- Flexible Workflow-Design

- Run processes reliably

- With integrated machine-communication

- Cell-controller functionallity

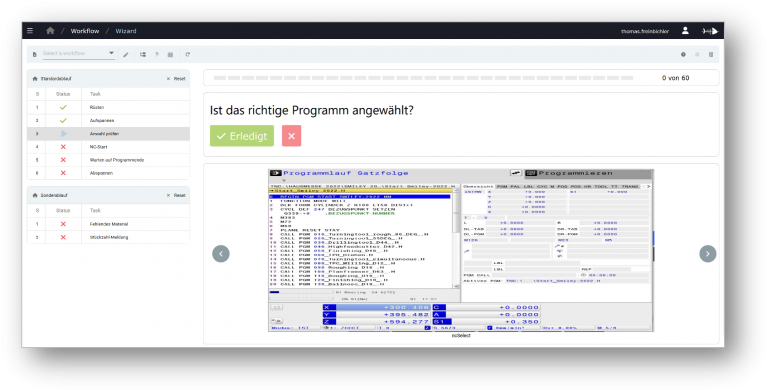

Wizard

The wizard enables guided processes and ensures their correct execution.

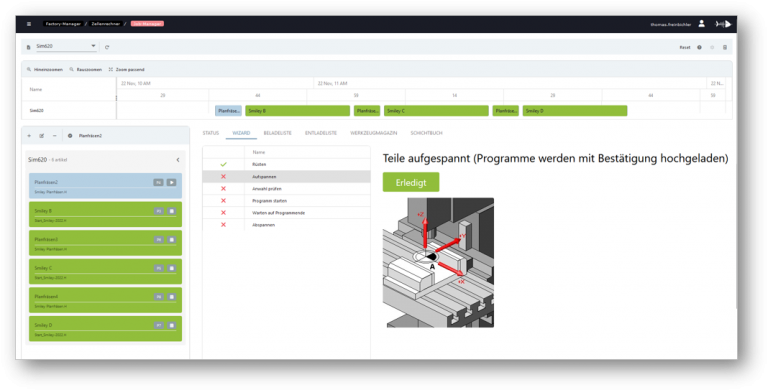

Job-Manager

The job manager is the cell-controller for stand-alone machines, including machine allocation planning, resource checks and our wizard.

Timeline

The representation of workflow events over time

- Add-ons can be used with all modules

- Reports, Dashboard, Shiftbook, Messenger, Notifier, ...

Dashboard

The Management-Dashboard is designed individually in a grid format and contains for example tables, charts, KPI's, pdf's, counters, webviews or external documents.

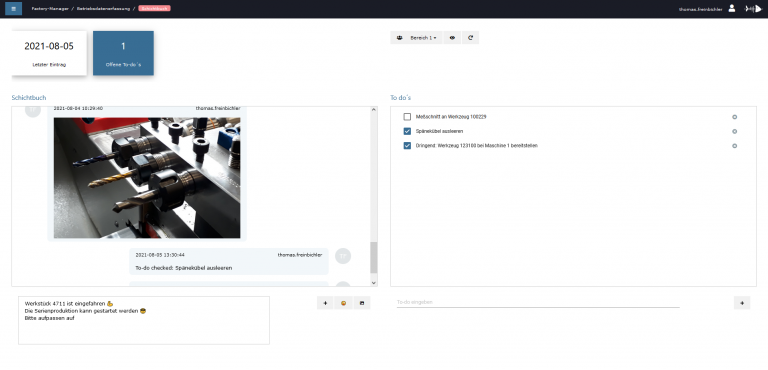

Shiftbook

The digital logbook in messenger format for easy communication and documentation, also with automatic entries.

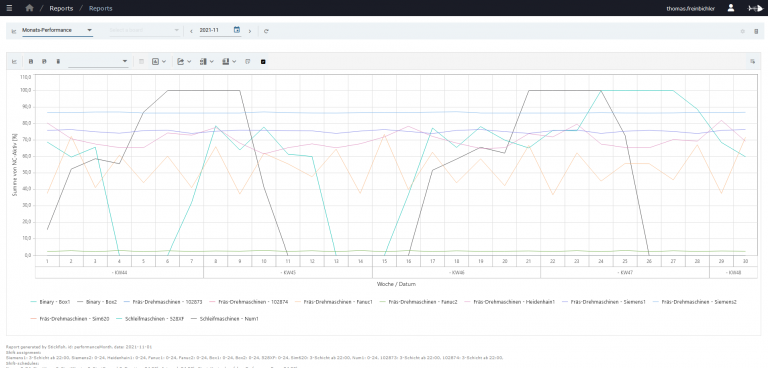

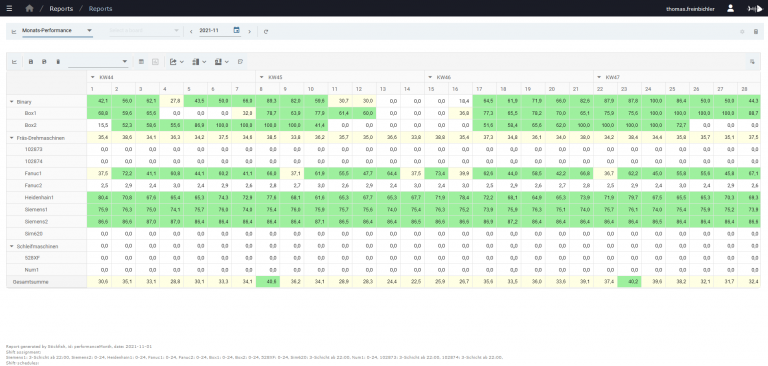

Reports

Easily configurable reports in table or chart format.

Messenger

The information comes to you. the daily, weekly or monthly report in your inbox.

Notifier

The notifier triggers notifications in case of certain events. For example, certain error codes or downtimes over a longer period of time.

My-Lists

Bring the many individual lists into a system that can be evaluated. Whatever - whether stock levels, standard values or even master data.

No idea how to start?

Or your team needs periodical support?

Use our online coaching

Starting Digital Lean-Management will be easy

We don’t just provide our apps.

In addition, we can support you with advice and training.

A great advantage, especially when you start using digital lean tools.

Or as a regular fixed point in addition to day-to-day business.

testimonials

What customers say